Equipment Management (FSSC 22000 Version 6)

페이지 정보

본문

Equipment Management (FSSC 22000 Version 6)

A.Introduction

FSSC 22000 additional requirement 2.5.15 on equipment management is applicable to all food chain categories, except subcategory FII on brokering and trading.

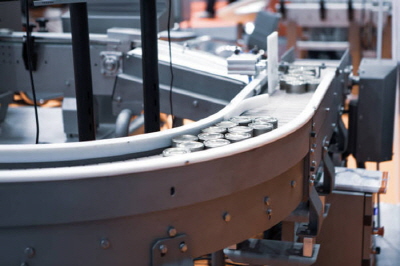

< Manage food equipment 1 >

The definition of equipment as per GFSI (v2020.1) is as follows:

Machines and equipment (including their parts and components necessary to link them together, and their services and utensils necessary for their operation), feed and food transport systems to bring ingredients/packaging to them, together with food storage and display units to allow the processing and retail of food, feed and packaging materials in GFSI scopes of recognitions.

The equipment management requirement included within the Scheme has been incorporated to ensure hygienic design has been taken into consideration at the purchasing stage, as well as to ensure that the associated risks of new equipment or changes to existing equipment have been considered within the organization's FSMS.

Hygienic design is a design that minimizes the risk of contributing to the microbiological, chemical, and physical contamination of food. It ensures the equipment accommodates and withstands the cleaning, sanitizing, and inspection processes involved. The equipment's hygienic design enables it to hold up against high temperature and high-pressure washdown, including, where applicable, exposure to cleaning chemicals depending on the industry.

Good hygienic design of equipment can have a significant impact on the safety of the food to be consumed, and if done incorrectly, it would have adverse effects on the people who consume the final products and the brand integrity of the manufacturing organizations.

Principles of hygienic design include:

• Accessibility

• Cleanability

• Drainability

• Material compatibility

• Segregation

• Surface and Geometry

GFSI also identifies equipment hygienic design to be of importance in the food industry and has specific requirements for Category JI and JII organizations1. Although the FSSC 22000 Scheme does not cover Category JI and JII, some of these requirements identified by GFSI for the hygienic design of equipment is a valuable source of information for organizations to consider when implementing the FSSC 22000 Additional Requirement 2.5.15 on Equipment Management.

< Manage food equipment 2 >

B.FSSC 22000 Requirement

Part 2 – Requirements for organizations to be audited in Version 6

2.5.15 Equipment Management (All food chain categories, excluding FII)

In addition to clause 8.2.4 of ISO 22000:2018, the organization shall:

a) Have a documented purchase specification in place, which addresses the hygienic design, applicable legal and customer requirements, and the intended use of the equipment, including the product handled. The supplier shall provide evidence of meeting the purchase specification prior to installation.

b) Establish and implement a risk-based change management process for new equipment and/or any changes to existing equipment, which shall be adequately documented, including evidence of successful commissioning. Possible effects on existing systems shall be assessed, and adequate control measures determined and implemented.

< Manage food equipment 3 >

C.Guidance for implementation

1. General Guidance

In the context of the FSSC 22000 Scheme, this requirement relates to significant changes to equipment, which can affect its hygienic design. It does not cover maintenance-related activities such as changing a fuse or replacing a fraying conveyor belt. This is addressed under the maintenance section of the relevant PRP sector-specific standard, such as clause 8.6 of ISO/TS 22002-1. Whereas modifications such as installing an additional conveyor belt to an existing line for the purpose of speeding up production would be considered a significant change that would require a review of the design of the existing line, and therefore a hygienic design risk assessment would be required. Another example would be installing a stainless-steel tray beneath a conveyor belt that transfers bread rolls from the cooling line to a packing machine to minimize the build-up of product crumbs beneath the packing line.

2. Purchase Specification

In accordance with 2.5.15 (a), an organization shall have a documented purchase specification in place that addresses the hygienic design, applicable legal and customer requirements, and the intended use of the equipment, including the product handled.

It is important for food safety management that expectations and interpretations of needs, capabilities, and intended use are clear during the development, realization, or handover of food processing equipment when it is newly purchased from the manufacturer.

In accordance with the requirement, the organization needs to document a purchase specification for each piece of equipment prior to purchasing the equipment. This specification needs to address the specific hygienic design parameters for the specific type of equipment being ordered/manufactured.

The intended use of the equipment must be specified, including the product handled, e.g., burger patty packing machine or corn chip fryer, etc. To establish the purchase specification, the organization should conduct an equipment design risk assessment that takes into account the intended use of the equipment, food safety hazard identification, and evaluation (risk assessment).

The design of the equipment must ensure that the equipment is suitable for the intended use and that (potential) contamination of the product is minimized. This can include features such as seethrough covers over the burger patty forming line to minimize handling of the products by the operator or a fail-safe lid for the fryer to control/limit opening and closing while the frying process is taking place. Recognized hygienic design standards for the specific industry should be considered. The specification must be documented and implemented every time new equipment is planned to be purchased.

Organizations should also include a requirement in the purchase specification that the equipment manufacturers have the responsibility of informing the organization of any food safety risks that could not be eliminated by hygienic design and also of providing the organization with an instruction manual covering information needed for hygienic safe operation within the limits of use of the respective equipment.

This includes but is not limited to:

• Instructions regarding limitations and operational use

• Instructions regarding technical measures (e.g., control or inspection devices)

• Instructions regarding disassembling for inspection, cleaning, and maintenance

• Instructions for cleaning

A service-level agreement should be drawn up between the supplier/manufacturer and the purchasing organization.

In accordance with 2.5.15 (a), the supplier shall provide evidence of meeting the purchase specification prior to installation.

The equipment manufacturer/supplier must provide evidence of meeting the purchase specification(s) and the requirements set out therein, including any customer and regulatory requirements, e.g., the manufacturer's manual can be compared to the purchase specification and evidence of this review maintained.

3. Risk-based Change Management Process

In accordance with 2.5.15 (b), an organization shall establish and implement a risk-based change management process for new equipment and/or any changes to existing equipment, which shall be adequately documented, including evidence of successful commissioning.

The objective of change control is to handle changes in such a manner that the impact on food safety by a change is foreseen and not missed and that the correct mitigation actions and control measures are executed.

Change control consists of the organization undertaking a risk assessment, determining risk mitigation based on hygienic design principles as well as documenting the changes. The Food Safety Team should ensure that the relevant managers are aware of these requirements in order to ensure that the change management process is followed.

Installation and commissioning phase:

• Installation: During installation, check that the correct equipment has been received and has been installed according to the approved specification. For equipment that has been prefabricated (assembled and/or assigned) at the equipment suppliers' site, a factory acceptance test (FAT) should be performed by the purchasing organization at the supplier's site prior to delivery at the purchasing organization.

• Commissioning: After installation and before use at the organization's premises, it should be verified that all functional (operational) parameters and specifications, limits, and tolerances detailed in the purchase specification and user manual/guide can be met to achieve the required hygienic performance. A site-acceptance test (SAT) should be done after the equipment components are installed and commissioned at the organization and typically includes functional testing.

• The organization should conduct a validation study to confirm that newly installed equipment functions as designed according to the manual/guide. This should include food safety, quality, cleanability aspects, and cleaning validation activities. The validation, which may have been initiated and planned prior to equipment being built, should be completed as part of the process qualification, taking into consideration the planned or projected usage in production.

The organization should look to undertake the following (as applicable) if changes to equipment are planned:

• Update the hazard analysis.

• Update the cleaning and sanitation program (procedures, cleaning schedules, records, etc.). Establish whether outsourced services are required or whether cleaning and sanitation can be done internally.

• Update the maintenance program (procedures, maintenance schedules, equipment checks, etc.) and establish whether outsourced services are required or whether maintenance and servicing can be done internally.

• Update production records, if necessary.

• Review and update the environmental monitoring program.

• Review and update the allergen management program, if applicable.

• Review and update the training program, and train relevant personnel on updated procedures.

• Update any other relevant verification activities.

• Determine if additional resources are needed and whether they will be available should breakdowns or faulty operations be experienced with the equipment.

< Manage food equipment 4 >

D. Guidance for auditors

The following is a non-exhaustive list of questions that an auditor can use to assess the FSSC Additional Requirement 2.5.15:

• Are the purchase requirements established and known for all new equipment?

• Is there supporting documentation available for review, such as purchase specifications, commissioning reports, equipment user manuals, certification documents, etc., to confirm the hygienic design of the equipment and successful commissioning?

• Does it address the hygienic design of the equipment, the products handled, and the legal/customer requirements?

• Has the intended use been clearly identified, and the risks related to the equipment determined?

• Has a risk-based change-management process for new equipment or changes to existing equipment been established?

• Have the relevant updates been made to the FSMS based on the changes made to equipment? E.g., cleaning and maintenance schedules updated, environmental monitoring program updated, evidence of training available?

[Reference]

Guidance Document: Equipment Management (September 2023), Foundation FSSC

- 이전글Amd 1:2024 (Climate Action Changes) 24.06.25

- 다음글Notice of Change of Address 24.03.22

댓글목록

등록된 댓글이 없습니다.